Plastic Car Carpet High Frequency Welding Machine

- Information

- Product Description

- Video

- Download

Plastic Car Carpet High Frequency Welding Machine

Machine Features:

PLC control, touch screen operation.

Prestore of a large amount of technical parameters.

Set technology parameters digitally in different times.

Fault self-diagnosis and screen displaying.

Frame type structure, left and right cylinder lifting screen gate, with anti-falling safety device.

It can reliably identify different molds, automatically retrieve the set programming parameters, and put into production accurately and quickly

Specifications:

Type | Power KW | Frequency MHz | Tube model | Pressure T | Working electrode size | Remark |

YF-HFM8-B | 8 | 27.12 | 7T69R | 5T | Customized according to car carpet | pneumatic |

YF-HFM8-C | 7T69R | >5T | hydraulic touch screen display Automatic Power Tracking | |||

YF-HFM15-B | 15 | 8T85 | >10T | |||

YF-HFM15-C | 8T85 | >10T | ||||

YF-HFM25-B | 25 | 8T25R | >10T | |||

YF-HFM25-C | 8T25R | >10T | ||||

| YF-HFM35-B | 35 | 8T87R | >10T | |||

| YF-HFM35-C | 8T87R | >10T |

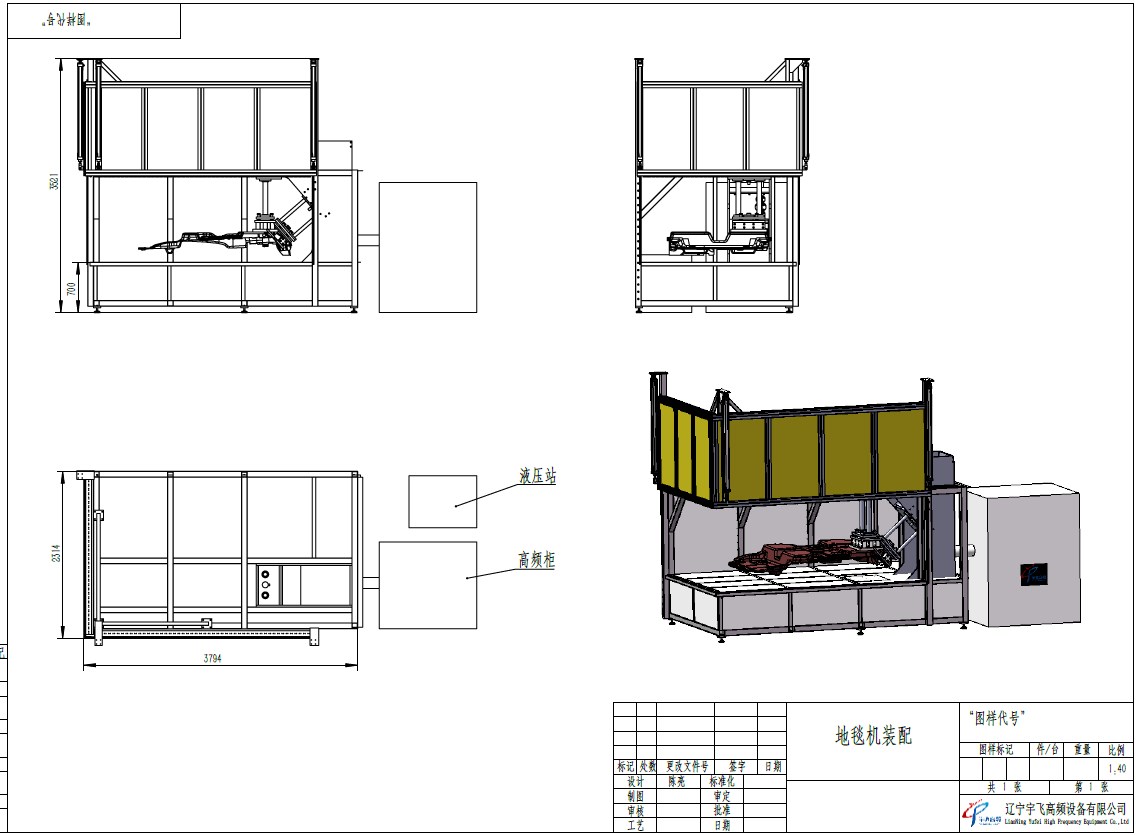

Plastic Car Carpet High Frequency Welding Machine:

Suitable for automotive carpet welding work. It can weld a variety of material combinations, and can weld wire loop carpets, velvet blankets, and velvet blankets + velvet blankets and other forms.

About Plastic Car Carpet High Frequency Welding Machine:

Since 1986, our company has provided high-frequency welding equipment for major automotive interior manufacturers for a long time, and has rich experience in equipment research and development and design.

The high-frequency automobile carpet welding machine has a complex and perfect circuit design. It can effectively avoid the interference of electric field radiation on other electronic equipment, and can achieve radiation values far superior to national standards, keep equipment running stably and reliably, and effectively reduce failure rates.

Key introduction: power automatic tracking function

This function is our company's patented technology, which can adapt to material changes, intelligently feedback and adjust process parameters, and effectively ensure the effect and quality of heat sealing.

Plastic Car Carpet High Frequency Welding Machine details:

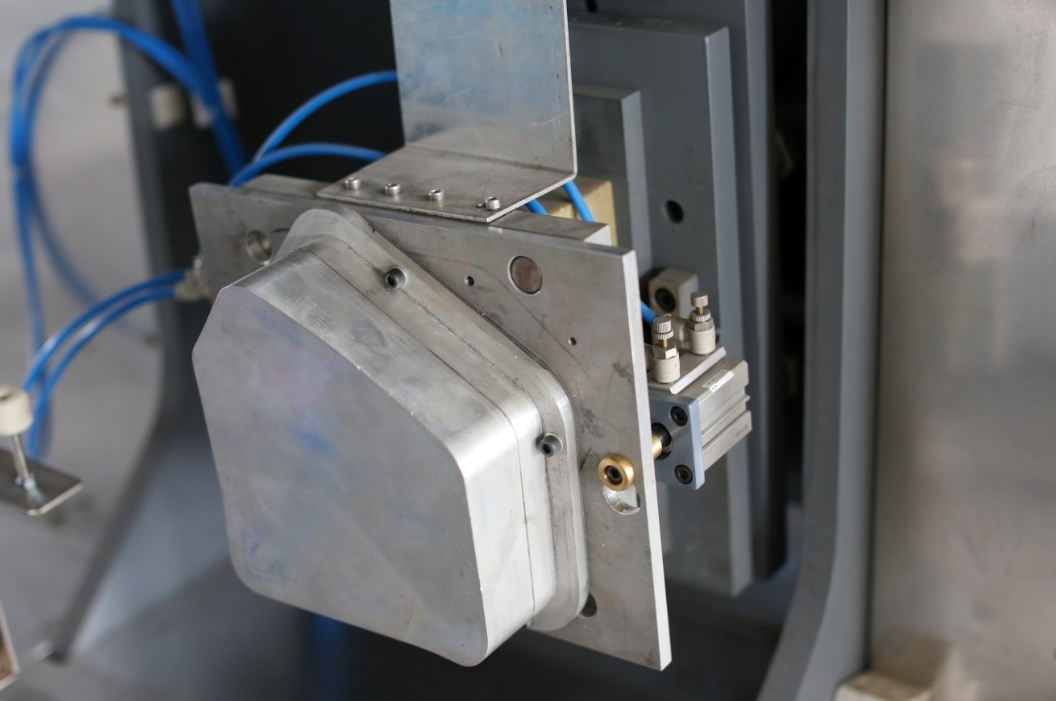

Mold installation adopts pneumatic clamping method. It is convenient and quick to change the mold.

Plastic Car Carpet High Frequency Welding Machine structure:

L-shaped safety door, open space, easy to feed.

PLC touch screen control, can pre-store a variety of welding recipes.