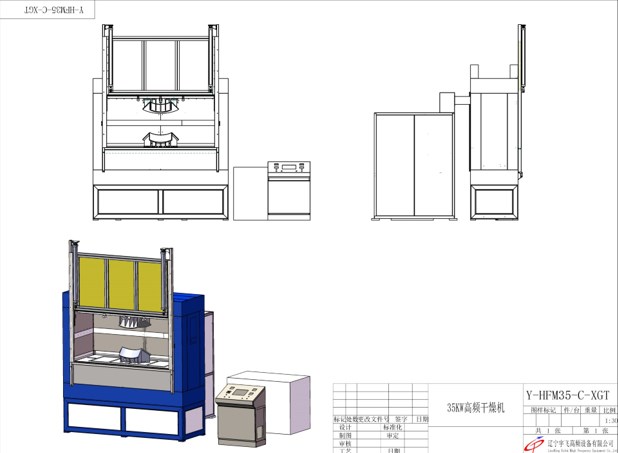

Radio Frequency Transformer Angle Cap Dryer

- Information

- Product Description

- Video

- Download

Radio Frequency Transformer Angle Cap Dryer

Machine General Features:

1, peripheral high frequency electromagnetic shielding device.

2, four-post type compressor, high strength, good rigidity.

3, the Japanese original 8T25 and domestic 834 Toshiba electron tubes for choice.

4, high sensitive spark discharge protection device.

5, hydraulic air cooling, can be used in high temperature environment.

6, the equipment can work continuously for a long time.

Specifications:

Model | Power Kw | Frequency | Tube model | Pressure | Working electrode size mm | Remark |

YF-HFM15-B | 15-50Kw | 27.12MHz | 8T85 | >20T | 600×1000 | hydraulic touch screen display Automatic Power Tracking |

YF-HFM15-D | 8T85 | >20T | 600×1000 | |||

YF-HFM25-B | 8T25R | >20T | 600×1000 | |||

YF-HFM25-D | 8T25R | >20T | 600×1000 | |||

YF-HFM35-B | 8T87R | >30T | 700×1200 | |||

YF-HFM35-D | 8T87R | >30T | 700×1200 |

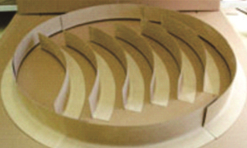

Radio Frequency Transformer Angle Cap Dryer application range:

High frequency drying equipment is mainly used for drying and forming products such as insulating cardboard.At the same time the machine can be used for wood drying.

About Radio Frequency Transformer Angle Cap Dryer:

High-frequency heating is to repeatedly polarize the heated material molecules, resulting in severe friction and self-heating from the inside out. It does not need any preheating and heat conduction, so its heating efficiency is very high.

Due to the rapid evaporation of water from the surface during the heating process of the material, and the surface heat dissipation condition is better than that of the inner layer, the temperature of the inner layer will be slightly higher than that of the outer layer. According to the material drying theory: the migration direction of the vapor pressure and the heat transfer direction accompanying the heating process A consistent state is best for drying the material. This heating method not only makes the inside dry quickly and thoroughly, but also completely avoids the phenomenon of external coke and internal growth.

Due to the characteristics of simultaneous heating inside and outside the high-frequency electric field, it is also more suitable for simultaneous heating of thick insulating materials or multi-layer materials.

Hf dryer details:

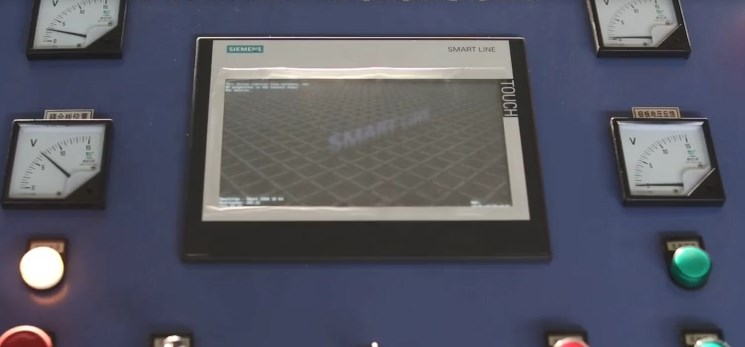

When the equipment is working, the screen door is closed to effectively reduce electromagnetic radiation.

Starting the device requires two hands to ensure safety.

PLC touch screen control, multiple sets of parameters can be pre-stored, making the operation easier.

Radio Frequency Transformer Angle Cap Dryer structure: